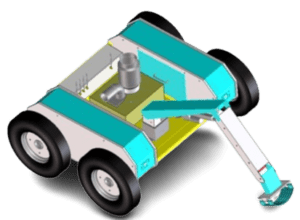

The Rover Scout One is a new product designed to operate remotely in hazardous, unstable or difficult-to-access environments, helping to reduce the exposure of personnel working in the field and significantly increase operational safety.

The system can be controlled directly by operators remotely or programmed to follow predefined routes in automatic mode, ensuring high adaptability to different intervention scenarios. Integration with B View software (Brochesia software) allows centralised management from the operations centre, with the ability to view the environment in which it operates through on-board cameras.

The Rover is designed for reconnaissance and inspection activities, with real-time image and data transmission, allowing for immediate analysis and timely operational decisions.

Thanks to its modular architecture, it can be configured with accessories dedicated to sampling, object handling or signal positioning, making it a versatile solution for emergency response, HazMat operations and environmental monitoring activities.

-

Operational functions

- Remote reconnaissance and inspection: exploration and assessment of dangerous, unstable or difficult-to-access scenarios via remote control.

- Autonomous and assisted driving: direct remote control or programmed navigation on predefined routes for high operational adaptability.

- Real-time video monitoring: smooth transmission of video and data streams to the command centre through native integration with Brochesia B View software.

- Immediate decision support: instant analysis of images transmitted by on-board cameras to facilitate timely and safe operational decisions.

-

Technical features

- Modular architecture: versatile structure that allows rapid reconfiguration based on the specific mission.

- Dust sampling and extraction system: kit dedicated to sample collection and contaminant detection in critical areas.

- Handling and manipulation: mechanical arm for managing and moving objects in high-risk environments.

- Signalling and marking modules: accessories for positioning markers on the ground during remediation or reconnaissance activities.

- Recharging station and logistical support: dedicated infrastructure to ensure operational autonomy and transport (trailer).

-

Use cases

- Emergency Management and HazMat Operations: rapid response in crisis situations for inspection and monitoring without exposing personnel to hazardous substances.

- Industrial Plant Inspection: inspection of high-pressure pipelines and complex infrastructure, reducing the risks associated with manual maintenance.

- Critical Infrastructure Maintenance: monitoring bridges, dams and power lines located in inaccessible or structurally unstable areas.

- Environmental Monitoring and Research: data collection and dust sampling in industrial areas or remote natural environments for scientific and safety analysis.